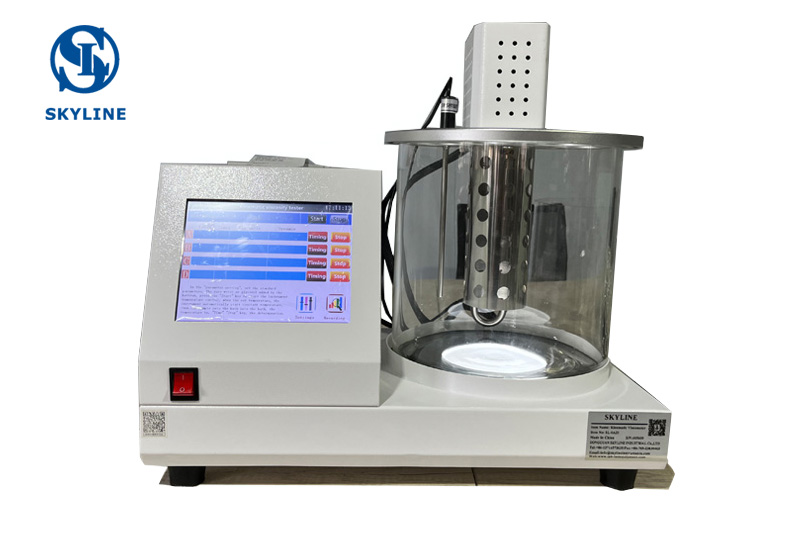

The lubricating oil oxidation stability tester is designed and manufactured according to SH/T 0193 and ASTM D2272. It is applicable to determine the oxidation stability of new and in-service turbine oils with the same composition (base oil and additives).This instrument is designed and manufactured according to the national standard GB265 Petroleum Products Kinematic Viscosity Determination Method, suitable for determining the kinematic viscosity of liquid petroleum products (refers to Newtonian liquids), its unit is mm2/s, it is a constant temperature, the determination of a certain volume of liquid under gravity flow through a calibrated glass capillary viscometer time, the viscometer's capillary constants and the flow of time The product of the capillary constant of the viscometer and the flow time is the kinematic viscosity of the liquid at that temperature. The product of the kinematic viscosity and the density of the liquid at the same temperature is the dynamic viscosity at that temperature.

Technical features:

①Chinese and English liquid crystal display, touch operation

②Automatic calculation, automatic printing, automatic storage of viscosity results

③Heater, stirring and other parts made of stainless steel, plastic spraying shell treatment, corrosion resistance and durability

④The number of experiments can be adjusted from 1 to 4 times, and the history of experimental records can be saved for convenient enquiry.

Technical parameters:

The number of holes of liquid bath: 4 holes

Temperature control accuracy:±0.02°C

Temperature control range: room temperature -100°C

Input power supply: AC220V±10V 50Hz

Heating power: less than 1500W

Ambient temperature:0℃~40℃Relative humidity:<80%.