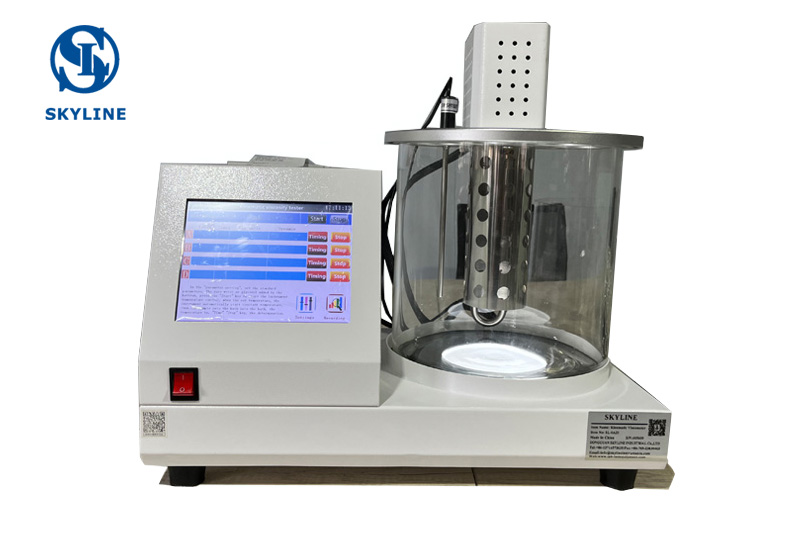

It is designed and manufactured according to the methods stipulated in GB/T 17623 and DL/T 703 standards, and is suitable for analyzing oil-filled electrical equipment (including transformers, reactors, current transformers, voltage transformers, charging bushings, etc.) Analysis of hydrogen, carbon monoxide, methane, carbon dioxide, ethylene, ethane, acetylene and other gas content in oil.

Technical features:

Realize computer real-time control and data processing:

High-precision, stable and reliable temperature control system:

The heater will stop heating and report the fault location on the display;

Simple and clear man-machine dialogue interface, easy to operate, easy to learn and use

Double stable high-precision air path control system.

The column chamber adopts the method of tracking temperature rise.

The instrument detects low-level hydrocarbons and high-level CO and CO2, which can be detected separately to avoid mutual interference.

Technical parameters:

|

Hydrogen Flame Ionization Detector (FID) |

Cylindrical collector structure design, metal nozzle |

|

Detection limit |

≤2×10-12g/s (n-hexadecane/isooctane) |

|

Baseline noise |

≤2×10-13A |

|

Baseline drift |

≤2×10-12A/30min |

|

Linearity |

≥106 |

|

Adjustable fully automatic ignition, stabilization time |

30 minutes |

|

Thermal Conductivity Detector (TCD) |

Semi-diffused structure, constant current control mode for power supply |

|

Sensitivity |

≥5000mV·ml/mg |

|

Baseline noise |

≤10μV |

|

Baseline drift |

≤100μV/30min |

|

Linearity |

≧105 |

|

Temperature range |

5°C~420°C above room temperature Accuracy ±0.1°C |

|

Power supply |

220V±22V, 50Hz |

|

Power |

≥2kW |

|

Weight |

55KG |

|

Dimensions |

60cm×50cm×50cm |