In the realm of materials science, two critical concepts often under scrutiny are oxidative stability and thermo-oxidative stability. Although both terms may seem interchangeable at first glance, they hold distinct meanings, each carrying significant implications for various industries.

Oxidative Stability: Guarding Against Oxygen's Effects

Oxidative stability refers to a material's ability to resist chemical reactions in the presence of oxygen. Oxygen, while vital for sustaining life, can be detrimental to many materials, causing corrosion, degradation, and even spoilage. A substance that possesses high oxidative stability can effectively withstand the damaging effects of oxygen exposure over time. This property is of paramount importance in industries such as food preservation, where maintaining the freshness and quality of products is crucial.

Thermo-Oxidative Stability: Withstanding High-Temperature Challenges

On the other hand, thermo-oxidative stability delves into a material's resistance to oxidation at elevated temperatures. High temperatures can accelerate chemical reactions, making them a critical factor in assessing a material's stability, especially in applications involving heat exposure. Thermo-oxidative stability is particularly relevant in fields like polymer manufacturing, where plastics and other materials must withstand processing temperatures without undergoing undesirable chemical changes.

Distinguishing the Two Concepts

To better understand the difference between these stability types, let's consider an analogy. Think of a piece of fruit—a fresh apple. Oxidative stability would be akin to the apple's ability to resist browning when exposed to air over time. A high oxidative stability would mean that the apple remains crisp and unblemished for an extended period. Now, imagine subjecting the apple to heat, like baking it in a pie. Thermo-oxidative stability is comparable to the apple's ability to maintain its texture and flavor despite the elevated temperature.

Applications and Testing

Industries that rely on materials with exceptional oxidative stability include the food and beverage industry, where antioxidants are often added to extend the shelf life of products. In contrast, thermo-oxidative stability plays a vital role in sectors involving high-temperature processes, such as the automotive industry, where materials used in engines and exhaust systems must withstand extreme heat conditions.

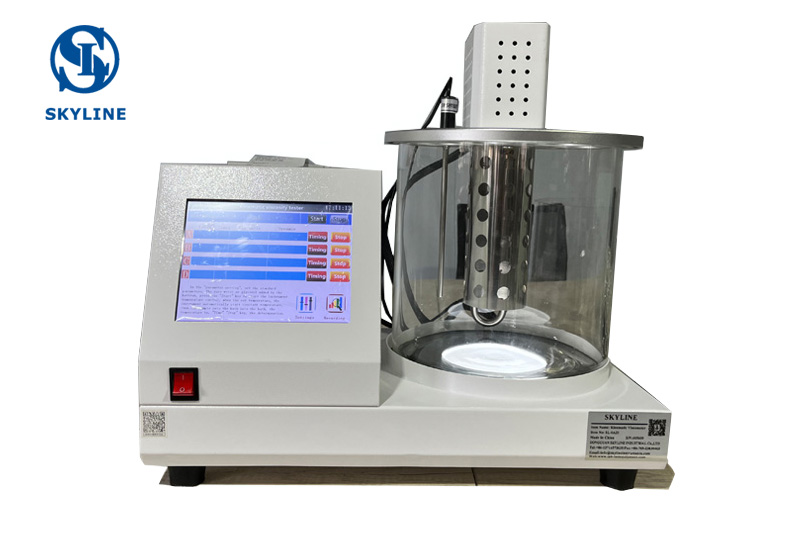

Testing for these stability properties involves subjecting materials to controlled conditions that mimic real-world scenarios. Oxidative stability can be evaluated by exposing a material to oxygen-rich environments, while thermo-oxidative stability testing typically involves subjecting materials to elevated temperatures and monitoring their response over time.

In conclusion, while both oxidative and thermo-oxidative stability pertain to a material's ability to resist oxidation, they address different aspects of this critical property. Understanding these distinctions is essential for researchers, engineers, and industries striving to develop and utilize materials with the desired stability characteristics for specific applications.