In the realm of power transmission and distribution, one crucial aspect often overlooked but of paramount importance is the Breakdown Voltage or Dielectric Breakdown (BDV) of Transformer Insulating Oil. This critical characteristic determines the insulating capability of the oil used in power transformers and plays a pivotal role in ensuring the safety and reliability of the power grid.

Transformer Insulating Oil is utilized to insulate and cool the electrical windings within power transformers, which are integral components in the power grid. These transformers step-up or step-down voltage levels for efficient power transmission across long distances. The insulating oil acts as a barrier to prevent electrical discharges and serves as a coolant to maintain optimal operating temperatures.

The Breakdown Voltage is the voltage level at which the insulating oil's dielectric properties break down, leading to a sudden and unwanted electrical discharge. This breakdown can result in arcing, which can severely damage the transformer and, in the worst-case scenario, lead to catastrophic failures, power outages, and even pose safety risks to people and equipment in the vicinity.

Several factors can influence the BDV of transformer insulating oil, including its chemical composition, purity, and the presence of contaminants. Over time, oils can degrade due to thermal stress, oxidation, moisture, and the accumulation of impurities, reducing their dielectric strength. Regular testing and analysis of the insulating oil are therefore imperative to detect any potential issues and prevent transformer failures.

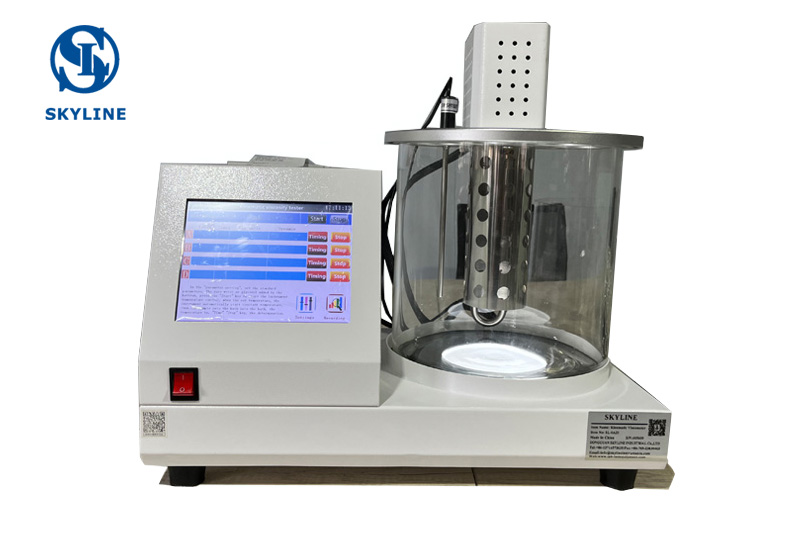

Experts emphasize that routine oil testing and monitoring are essential to maintaining transformer health and predicting potential failures before they occur. Utilities and power companies frequently employ diagnostic tests, such as the BDV test, to assess the dielectric strength of transformer oil. The test involves applying an increasing voltage to a sample of the oil until electrical breakdown occurs. The voltage level at which this occurs indicates the BDV of the oil.

Furthermore, advancements in technology have led to the development of smart monitoring systems that can continuously assess the condition of transformer insulating oil. These systems can provide real-time data, enabling power grid operators to make informed decisions about maintenance and prevent catastrophic transformer failures.

The importance of Breakdown Voltage of Transformer Insulating Oil extends beyond traditional power grids. It also plays a crucial role in renewable energy sources like wind and solar farms, where transformers are used to connect the generated power to the grid.

In light of the increasing demand for electricity and the need for a more robust and resilient power infrastructure, governments and power utility companies are investing in research and development to improve insulating oil technologies. This includes exploring alternative, eco-friendly insulating oils that have higher BDV and better resistance to degradation, ensuring a more reliable and sustainable power supply.

In conclusion, the Breakdown Voltage of Transformer Insulating Oil remains a critical aspect in the power industry's pursuit of a safe, reliable, and efficient power grid. By continually monitoring and maintaining the dielectric strength of transformer oil, power utilities can mitigate the risks of transformer failures and ensure uninterrupted power supply to consumers and industries alike.