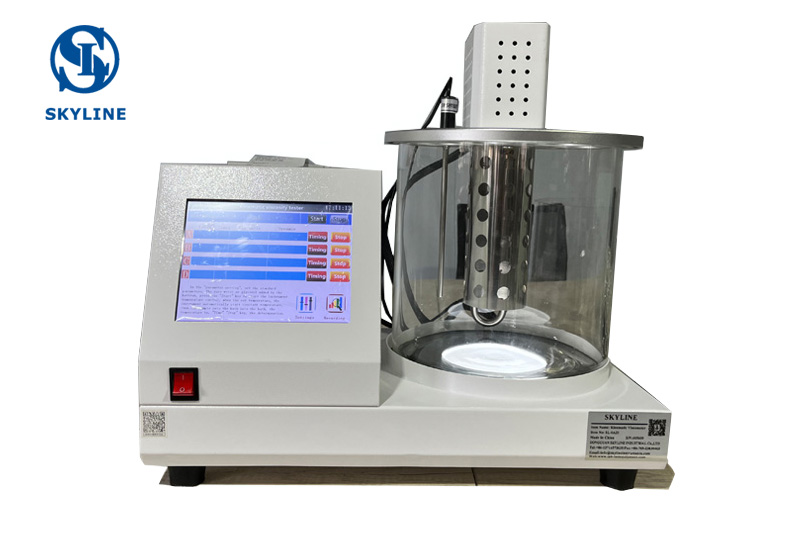

The function of a dielectric strength tester for insulating oil is to measure the dielectric strength or breakdown voltage of the oil. Insulating oils, such as mineral oils or synthetic oils, are commonly used in high-voltage electrical equipment like transformers, capacitors, and circuit breakers. It is crucial that these oils possess excellent dielectric properties to effectively insulate and prevent electrical breakdown between conductive components.

The dielectric strength of an insulating oil is the maximum voltage it can withstand before electrical breakdown occurs and a spark or arc is formed through the oil. If the dielectric strength is not sufficient, it can lead to insulation failure, resulting in equipment damage, power outages, and potential safety hazards.

The dielectric strength tester applies an increasing voltage to a sample of insulating oil until a breakdown occurs. This is typically done by gradually raising the voltage level until a visible arc is detected within the oil sample. The voltage at which this breakdown occurs is recorded as the dielectric strength of the oil. The breakdown voltage is usually expressed in kilovolts (kV) or kilovolts per millimeter (kV/mm).

Regularly testing the dielectric strength of insulating oil is an essential part of preventive maintenance for high-voltage electrical equipment. By monitoring the dielectric strength, operators can identify any deterioration in the oil's insulating properties and take corrective actions, such as oil purification, replacement, or other maintenance activities, to ensure the equipment continues to operate safely and efficiently.