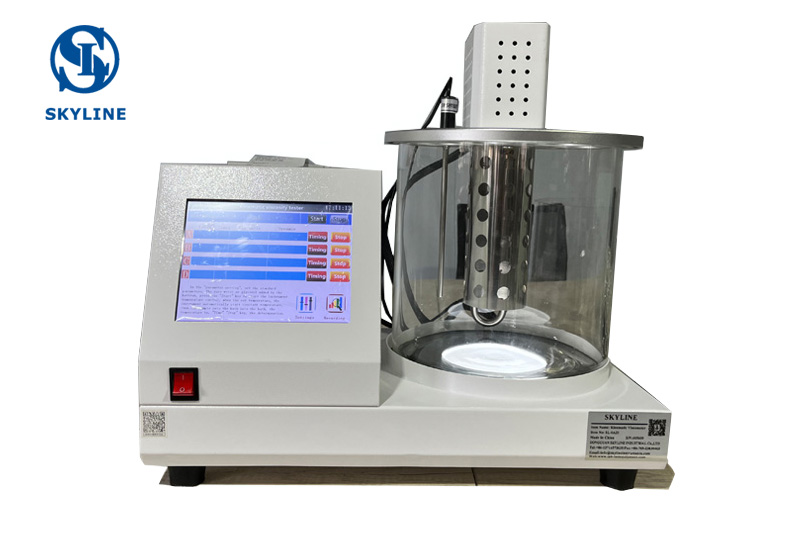

The Engine Oil Cold Crank Simulator (CCS) is a fundamental tool used in the petroleum industry to determine an engine oil's low-temperature viscosity performance. As part of the ASTM D5293 standard, the CCS test plays a critical role in evaluating an oil's ability to start an engine in cold weather conditions. Understanding the significance of CCS and its application in ASTM D5293 is crucial for ensuring the efficiency and reliability of engines in challenging climates.

- The Basics of CCS

The Cold Crank Simulator (CCS) is a device designed to measure an engine oil's viscosity at low temperatures. It simulates the conditions that an engine experiences during cold starts, where the oil tends to thicken due to low temperatures. The CCS test helps determine the oil's ability to flow and lubricate the engine's components effectively during startup, ensuring a smooth and reliable engine operation even in extreme cold conditions.

- Importance in ASTM D5293

ASTM D5293 is a widely recognized standard used to evaluate the low-temperature viscosity performance of engine oils. It provides an essential benchmark for selecting oils that meet the requirements for specific engine types and climatic conditions. The CCS test is one of the essential tests outlined in ASTM D5293, and its results are used to classify engine oils into viscosity grades.

- Ensuring Engine Reliability

Engines subjected to cold starts are at greater risk of wear and tear, as the oil's increased viscosity may hinder proper lubrication during initial operation. By using the CCS test, engine oil manufacturers and users can determine whether the oil will provide sufficient protection during critical moments when the engine is most vulnerable to damage.

- Preventing Engine Damage

Using an engine oil that fails to meet the appropriate low-temperature viscosity requirements can lead to various problems, such as increased wear on engine components, reduced fuel efficiency, and even engine failure. A properly conducted CCS test ensures that the selected oil can flow promptly to all critical engine parts, reducing wear and protecting against premature engine failure.

- Enhancing Fuel Efficiency

In cold conditions, engine oil with poor low-temperature viscosity may not flow efficiently, leading to higher resistance in the engine's moving parts. This increased friction can result in higher fuel consumption. Choosing the right engine oil through CCS testing helps maintain optimal fuel efficiency, reducing operating costs and minimizing environmental impact.

- Meeting Climate-Specific Demands

Different regions experience a wide range of temperature variations, from extremely cold to tropical climates. Utilizing the CCS test enables manufacturers to formulate engine oils tailored to specific temperature requirements. This way, vehicle owners can be confident that their engines will start smoothly, regardless of the weather conditions.

- Continuous Improvements and Research

The importance of the CCS test also extends to research and development in the automotive and petroleum industries. The data obtained from CCS testing helps researchers identify trends and make improvements in engine oil formulations, leading to better-performing oils that meet the ever-evolving demands of modern engines.

Conclusion

The Engine Oil Cold Crank Simulator (CCS) is a crucial tool in ASTM D5293 for evaluating the low-temperature viscosity performance of engine oils. Its significance lies in ensuring engine reliability, preventing damage, enhancing fuel efficiency, and meeting climate-specific demands. The CCS test plays a vital role in producing high-quality engine oils that enable smooth engine operation even in the harshest of weather conditions, leading to longer engine life and improved overall performance. Manufacturers, mechanics, and vehicle owners alike should acknowledge the significance of the CCS test in selecting the right engine oil for their specific needs.