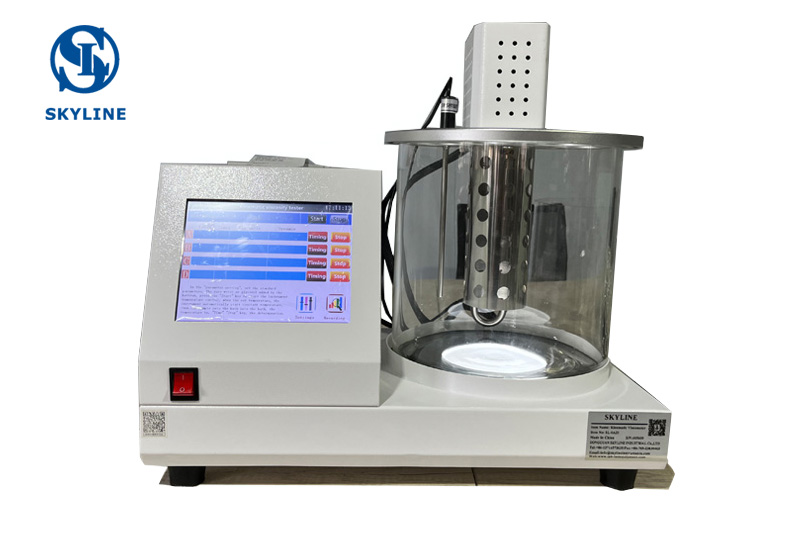

In the world of machinery and engines, oil serves as the lifeblood, keeping the mechanical heart pumping smoothly and efficiently. But have you ever wondered why measuring the kinematic viscosity of oil is crucial? Understanding this fundamental property is essential for maintaining the health and longevity of our machines. Let's delve into the reasons behind the significance of measuring kinematic viscosity.

What is Kinematic Viscosity?

Viscosity is a measure of a fluid's resistance to flow. In simple terms, it determines how thick or thin a liquid is. Kinematic viscosity, specifically, quantifies the oil's flow characteristics concerning temperature variations. It is expressed in centistokes (cSt) or stokes (St) and plays a pivotal role in determining the oil's ability to lubricate, cool, and protect the components of an engine.

Optimal Lubrication and Engine Performance

Different machinery and engines operate under diverse conditions, and a one-size-fits-all approach to oil selection simply doesn't suffice. Kinematic viscosity helps engineers and technicians to select the right oil grade for specific applications. When the oil's viscosity matches the manufacturer's recommendations, it ensures optimal lubrication, reducing friction between moving parts and preventing premature wear. This, in turn, improves the overall performance and efficiency of the engine.

Temperature Stability

Engines often endure extreme temperature fluctuations during operation. Oil with the appropriate kinematic viscosity can withstand these temperature changes without undergoing significant viscosity variations. High-temperature stability ensures that the oil remains effective in harsh conditions, maintaining its lubrication properties even under intense heat.

Avoiding Damage and Costly Repairs

Using oil with incorrect viscosity can have catastrophic consequences for machinery. If the oil is too thin (low viscosity), it may fail to create a sufficient lubricating film, leading to metal-to-metal contact and increased wear. Conversely, oil with high viscosity might not flow adequately, causing poor lubrication and excessive energy consumption. Both scenarios can result in significant damage to the engine and expensive repairs or even complete failure.

Fuel Economy and Emissions

Kinematic viscosity also has an impact on fuel economy and emissions. Oil with the right viscosity reduces friction, leading to smoother engine operation, which, in turn, can enhance fuel efficiency. Additionally, when the engine operates optimally, there is a potential reduction in harmful emissions, contributing positively to environmental preservation.

Predictive Maintenance and Extended Oil Life

Regularly measuring kinematic viscosity allows engineers to monitor the condition of the oil and the engine. By analyzing the trends in viscosity over time, it becomes easier to predict when the oil needs changing or when maintenance is necessary. This proactive approach can help prevent sudden breakdowns, increase the lifespan of machinery, and ultimately save on operational costs.

In conclusion, measuring the kinematic viscosity of oil is a vital aspect of maintaining machinery and engines in peak condition. It is not just about choosing the right oil grade; it also ensures optimal lubrication, temperature stability, and protection against wear and tear. By paying attention to this seemingly small detail, industries and businesses can avoid costly repairs, improve performance, and promote sustainable practices in their operations. The significance of kinematic viscosity measurement cannot be overstated, as it continues to be the key to unlocking the engine's full potential and extending its lifeblood.