Copper strip corrosion refers to the deterioration or degradation of copper metal when it comes into contact with certain substances. It is a significant concern in industries where copper is used, such as in the production, storage, and transportation of fuels, lubricants, and other petroleum-based products. Copper strip corrosion can occur due to the presence of impurities or additives in these products, which can react with the copper surface and lead to corrosion.

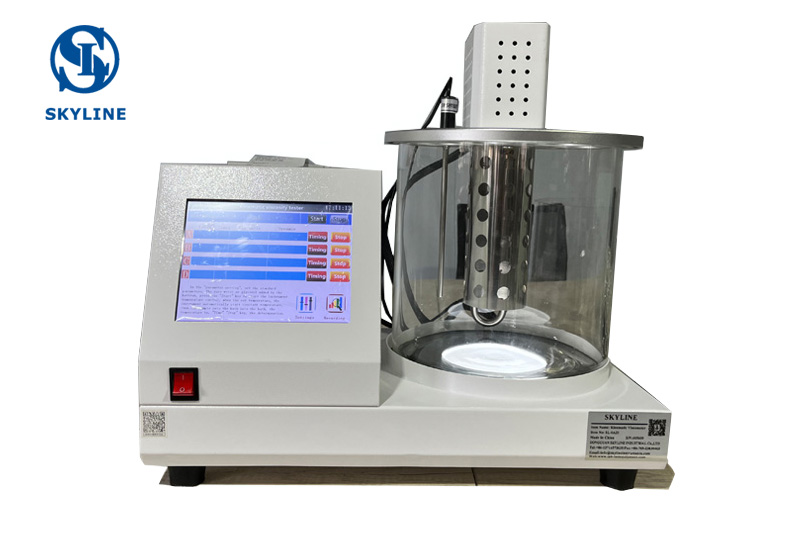

The copper strip corrosion test is a widely used method to evaluate the corrosiveness of petroleum products. It helps determine the likelihood of these products causing corrosion in equipment and storage facilities made of copper or copper alloys. The test involves exposing a clean copper strip to the petroleum product under specific temperature and time conditions. After the exposure period, the strip is visually examined for signs of corrosion, such as discoloration or tarnishing.

The importance of copper strip corrosion testers lies in their role in quality control and product development. Here are some reasons why these testers are essential:

-

Preventing Equipment Damage: Copper corrosion in fuel or lubricant systems can lead to damage in engines, pipelines, and storage tanks. By conducting copper strip corrosion tests, industries can ensure that their products meet acceptable corrosion standards and protect equipment from unnecessary wear and tear.

-

Regulatory Compliance: Many countries have regulations and standards in place to limit copper corrosion in petroleum products. Companies must comply with these regulations to ensure the safety and integrity of their products and avoid legal repercussions. Copper strip corrosion testers help verify compliance with these standards.

-

Performance Evaluation: Copper strip corrosion tests provide valuable information about how petroleum products perform under specific conditions. This data can be used to optimize product formulations and ensure they meet performance requirements in various applications.

-

Customer Confidence: Customers, especially in industries where copper-based equipment is prevalent, look for products that are less likely to cause corrosion-related issues. By conducting copper strip corrosion tests and ensuring product quality, companies can build customer trust and confidence in their brand.

-

Cost Savings: Identifying potential corrosion issues early in the product development stage can save companies significant costs related to equipment maintenance, repairs, and replacements.

In summary, copper strip corrosion is a critical aspect to consider in industries dealing with petroleum-based products. Copper strip corrosion testers play a vital role in quality assurance, regulatory compliance, and ensuring the longevity and performance of equipment and infrastructure.